What is Ultrafiltration(UF)?

Ultrafiltration (UF) involves pressure-driven separation of materials from a feed solution. The technology

is used to remove particulate and microbial contaminants, but it does not remove ions and small molecules.

Pressure drives the process, which typically operates with a feed pressure of 4 to 100 psig. UF plants are

automated and have low operational labor requirements. These systems, however, can require frequent

cleaning. UF membranes have a service life of three to five years or longer, which is comparable to reverse

osmosis membranes. UF modules are commercially available in tubular, hollow-fiber, plate and frame, and spiral

wound configurations.

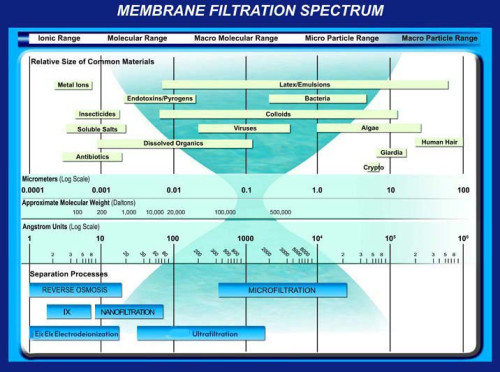

UF membranes reject solutes ranging in size from 0.03 microns and larger. Figure 1 provides a guide to the

relationship between common materials, separation processes, and pore size measurements. The UF

membrane process separates molecules in solution on the basis of size. The pore size and molecular weight

cut-off (MWCO) are often used to characterize a membrane. The pore size is the nominal diameter of the

openings or micropores in the membrane expressed in microns. The MWCO is the molecular mass or weight of

a solute that rejects greater than 90 percent. The unit of measurement for MWCO is the Dalton (D).

Different membrane materials with the same nominal MWCO may have differing solute rejection. Pore size

distribution and uniformity rather than the chemical nature of the membrane material may cause this effect.

Because factors other than pore size or MWCO affect the performance of membranes, challenge studies are

is used to remove particulate and microbial contaminants, but it does not remove ions and small molecules.

Pressure drives the process, which typically operates with a feed pressure of 4 to 100 psig. UF plants are

automated and have low operational labor requirements. These systems, however, can require frequent

cleaning. UF membranes have a service life of three to five years or longer, which is comparable to reverse

osmosis membranes. UF modules are commercially available in tubular, hollow-fiber, plate and frame, and spiral

wound configurations.

UF membranes reject solutes ranging in size from 0.03 microns and larger. Figure 1 provides a guide to the

relationship between common materials, separation processes, and pore size measurements. The UF

membrane process separates molecules in solution on the basis of size. The pore size and molecular weight

cut-off (MWCO) are often used to characterize a membrane. The pore size is the nominal diameter of the

openings or micropores in the membrane expressed in microns. The MWCO is the molecular mass or weight of

a solute that rejects greater than 90 percent. The unit of measurement for MWCO is the Dalton (D).

Different membrane materials with the same nominal MWCO may have differing solute rejection. Pore size

distribution and uniformity rather than the chemical nature of the membrane material may cause this effect.

Because factors other than pore size or MWCO affect the performance of membranes, challenge studies are

used to demonstrate membrane performance and benchmark different membranes.