Polypropylene and Fluoroplastics electric diaphragm pump for acid or alkali or corrosive liquid transportation

- PRODUCT DETAIL

Product introduction

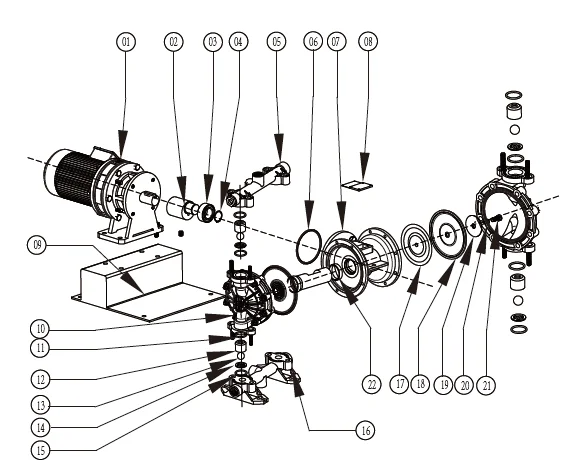

DBY series electric diaphragm pump mainly uses cycloid reducer technology. The crank slider mechanism drives the double

diaphragms to do reciprocating motion, which makes the workingc hamber volume changes occur alternately so as to keep

the liquid sucking and discharging.

Meanwhile,nowerdays, due to the breakthrough of diaphragm mater ials,more and more international industrialized countries

have adopted this type of pump, which replacing part of the cen trifugal pumps, screw pumps. T hey are widely applied to

petrochemical, ceramic and metallurgical industries.

Advantages

- Self-priming ability of more than 7 m without irrigation water.

- Good performance, particles below 10mm, slurry, etc. can effortlessly pass through.

- Since the diaphragm is separated from the transmission medium and transmission machinery.

-

The media will not be leaked out. And the pump itself is unsealed, which greatly extended

service life. Depending on the medium, the diaphragm can be divided into chloroprene rubber,

fluorine rubber, nitrile rubber, etc., which meet different customer needs. -

Medium flows through the pump part, according to customer requirements, are divided into

cast iron, steel, stainless steel, rubber lined. Motors can be divided into ordinary and

explosion-proof.

SCOPE OF APPLICATION

- A variety of toxic, flammable, volatile liquid

- Acids, alkalis, corrosive liquids

- High temperature media up to 150℃

- As a variety of filter first-level pressure device

- Recovering and recycling of hot water

- loading and unloading Tankers, oil depots and oil

- Pickles, jam, mashed potatoes, chocolate, etc.

- Pumping paint, rubber and paint binders

- Porcelain, glaze, cement, grout and slurry

- Latex rubber pulp, organic solvents and fillers

- Pumping sewage and residual oil from cruises or barges

- Hops and yeast slurry, syrup, molasses

- Pump sediment contaminants in shaft, tunnel,tunnels and sewers

- The delivery of a variety of special media

| DBY3-15 | DBY3S-15 | |

| Max.Flow | 3.4gpm(12.8Lpm) | 3.4gpm(12.8Lpm) |

| Max.Working Pressure | 58 psi(0.4 Mpa,4 bar) | 102psi(0.7Mpa,7bar) |

| Fluid Inlet Size | 3/8 in.npt(f) | 3/8 in.npt(f) |

| Fluid Outlet Size | 3/8 in.npt(f) | 3/8 in.npt(f) |

| Max.Suction Height(dry suction or wet suction) | 10 ft.(3m) | 10 ft.(3m) |

| Max.Permitted Grain | 3/32 in.(2.5mm) | 3/32 in.(2.5mm) |

| Every Reciprocating Flow | 0.04 gallon(0.15L) | 0.04 gallon(0.15L) |

| Max.Reciprocating Speed | 85 cpm | 85 cpm |

| Outlet Pressure | 0.4Mpa | 0.7Mpa |

| Motor power | 0.55 kW | 0.75 kW |

| Materials of main pump structure | cast steel,Aluminun alloy,PP stainles steel and PTFE | |